据美国物理学家组织网12月22日报道,美国塔夫斯大学工程学院生物工程师开发出一种无痛的丝微针系统,能在长时间里将药物缓慢释放,无需冷藏多余的药物。这种微针兼具生物适应性和生物降解性,可在正常的温度和压力下制造,能装载易受破坏的生化药品并保持其活性。相关论文发表在《先进功能材料》网站上。

演示试验表明,新式丝微针能以可控制的速度递送大分子、酶模型药物、辣根过氧物酶,同时还保持药物的生物活性;装载四环素的丝微针还能抑制金黄色葡萄球菌的生长,表明这种微针在递送治疗药物的同时,还具有预防局部感染的潜在价值。

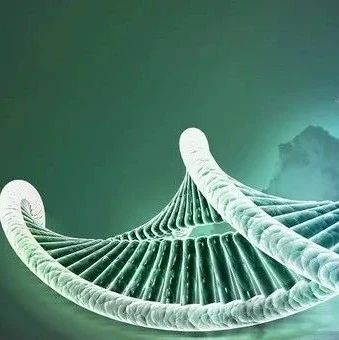

尽管有些药物可以直接吞服,但有些却无法承受胃肠道的消化分解。皮下注射的方式比较痛苦,也不能缓慢释放药物。只有很少的小分子药物能用贴敷的方式进入体内。丝微针仅1微米大小,能穿透上层皮肤而不会触及神经,是一种新的无痛式药物释放机制。但目前有很多难题阻碍了该技术的发展,如生物制品的脆弱性使药物在制造过程中丧失活性、不能精确控制药物释放或放药过多、微小的皮肤穿透带来的感染等。

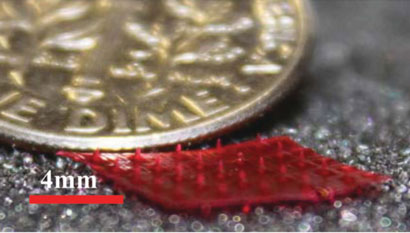

针对这些问题,研究人员开发出了新的制造程序,过程包括压力、温度和水处理等。他们用铝制成微针母模,排成500微米高,针尖半径不到10微米的阵列;用有弹性的聚二甲硅氧烷(PDMS)浇注在母模上形成凹模;再把装有药物的丝蛋白溶液注入凹模中。当丝干燥后,再把包含药物的丝微针取下来进一步加工。后处理包括用水蒸气使其变柔软,再通过温度、机械和电子的各种处理,使其具有相应的扩散率和药物释放速度。

研究人员表示,调节丝蛋白的后处理条件,如改变干燥时间,主要是控制它的次级结构,以能精确控制药物释放速度。经过释放动力模型测试,药物释放速度可以降低5.6倍。这解决了长期以来的药物释放难题,还能用在其他生物存储方面。

论文合著者、塔夫斯生物医学工程主席大卫·卡普兰还指出,这种微针非常灵活,能扩大或缩小、运输或存储无需冷藏,管理起来就像贴敷片或绷带一样容易。

Fabrication of Silk Microneedles for Controlled-Release Drug Delivery

Konstantinos Tsioris, Waseem K. Raja, Eleanor M. Pritchard, Bruce Panilaitis, David L. Kaplan, Fiorenzo G. Omenetto

Microneedles are emerging as a minimally invasive drug delivery alternative to hypodermic needles. Current material systems utilized in microneedles impose constraints hindering the further development of this technology. In particular, it is difficult to preserve sensitive biochemical compounds (such as pharmaceuticals) during processing in a single microneedle system and subsequently achieve their controlled release. A possible solution involves fabricating microneedles systems from the biomaterial silk fibroin. Silk fibroin combines excellent mechanical properties, biocompatibility, biodegradability, benign processing conditions, and the ability to preserve and maintain the activity of biological compounds entrained in its material matrix. The degradation rate of silk fibroin and the diffusion rate of the entrained molecules can be controlled simply by adjusting post-processing conditions. This combination of properties makes silk an ideal choice to improve on existing issues associated with other microneedle-based drug delivery system. In this study, a fabrication method to produce silk biopolymer microstructures with the high aspect ratios and mechanical properties required to manufacture microneedle systems is reported. Room temperature and aqueous-based micromolding allows for the bulk loading of these microneedles with labile drugs. The drug release rate is decreased 5.6-fold by adjusting the post-processing conditions of the microneedles, mainly by controlling the silk protein secondary structure. The release kinetics are quantified in an in vitro collagen hydrogel model, which allows tracking of the model drug. Antibiotic loaded silk microneedles are manufactured and used to demonstrate a 10-fold reduction of bacterial density after their application. The processing strategies developed in this study can be expanded to other silk-based structural formats for drug delivery and biologicals storage applications.

文献链接:https://onlinelibrary.wiley.com/doi/10.1002/adfm.201101536/abstract