摘要:黄金或白金经腐蚀形成微型网状孔道,再浸满生理盐水,就形成金属液体混合材料。这种材料属性的改变,是由一个电子信号触发,只需触摸一下按钮就可以。

世界首次演示:有一种材料,改变其强度只需要触摸一下按键。这种转变的实现,只需几秒钟,就可改变材料的电子结构;因此,举例而言,硬而脆的物质可以变得柔软可塑。使这项研发具有革命性的,是这种转变可以通过电信号控制。

这项世界首创起源于汉堡。雅格•维米勒(Jörg Weißmüller)是一位材料科学家,在德国汉堡理工大学(Technical University of Hamburg)和亥姆霍兹吉斯达中心(Helmholtz Center Geesthacht)工作,他已经开展了这项突破性的研究工作,合作的同事来自中国沈阳金属研究所(Institute for Metal Research in Shenyang)。

这位51岁的研究员来自德国萨尔州(Saarland),谈到他的基础研究,他说是打开一了扇大门,可以带来多种不同的应用,是“材料科学的一个突破。”这种新型金属高性能材料已经介绍过,作者是雅格•维米勒博士,就在最新一期的科学期刊《科学》(Science)上。举例而言,他们的研究成果可以制成未来的智能材料,这种材料具有自我修复能力,可以自动消除缺陷。

在坚固性方面,煮鸡蛋可随意调整,就根据烹煮时间调整。但是,有些决定是不可挽回的,煮硬的鸡蛋永远不能重新转变为煮软的鸡蛋。这样,也许会较少有烦恼,因为在早餐桌上,我们可以简单地来回改变鸡蛋不同程度的硬度。

类似的问题也会出现,因为要制造结构材料,比如金属和合金。这种材料的特性在生产中会进行彻底设置。这迫使工程师作出妥协,选择这种材料的机械性能。更高强度必然伴随着更大的脆性,这就降低了损伤容限(damage tolerance)。

维米勒教授是汉堡理工大学材料物理与技术研究所所长,也是亥姆霍兹盖斯达中心混合材料系统部(Hybrid Material Systems)主任,他表示:“正是在这一点上取得了重大进展。我们第一次制成一种材料,在使用时,可以来回转换状态,就在硬而脆的性能和软而可塑的状态之间转换。我们仍处于基础研究阶段,但我们的发现可能带来的,是显著地推进开发所谓的智能材料。“

金属和水的结合

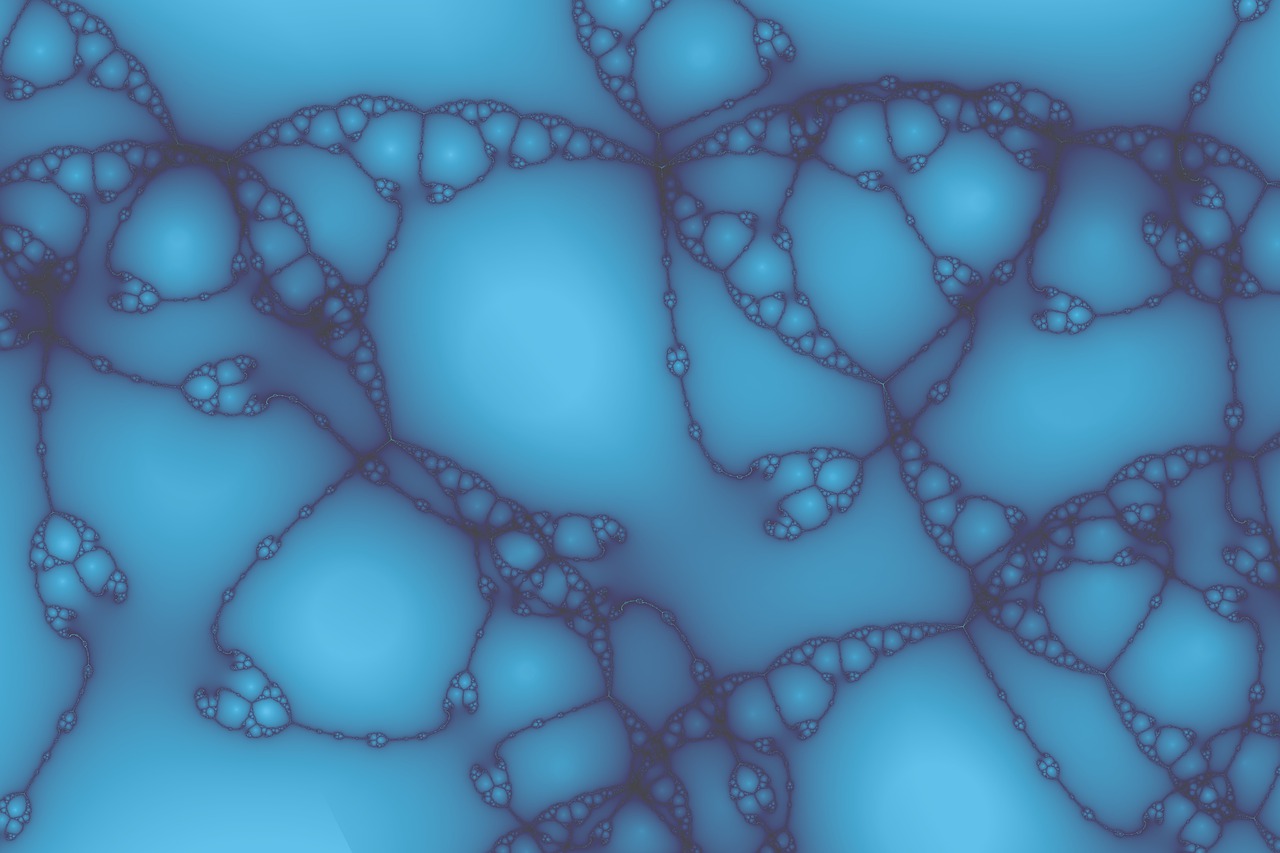

为了生产这种创新材料,材料科学家采用了一种相对简单的工艺:腐蚀。这类金属通常是贵重金属,比如黄金或白金等,它们被放进酸性溶液。从后果上看,腐蚀过程开始后,微型管道和孔洞会在金属中形成。这种新形成的纳米结构材料,充满网状孔道。

这些孔会浸透一种导电液体,例如,一种简单的生理盐水溶液(saline solution),或稀释酸,这样,一种真正的金属和液体的混合材料就产生了。这是一种不寻常的“联姻”,正如维米勒说,这种金属和水的结合是由一个电子信号触发,这样,材料属性的改变,只需触摸一下按钮就可以。

由于离子溶解在液体中,金属表面可带电。换句话说,金属方面力学性能的改变,可以采用液体方面的一个电势。这一效果可追溯到加强或减弱金属表面的原子键合,当额外的电子被加入或抽出表面原子时,就会这样。这种材料的强度可提高一倍,只要需要。另外,这种材料也可以切换到一种较弱状态,但具有更大的损伤容限,可吸收能量,而且具有可塑性。

具体应用仍然是将来的事情。然而,研究人员已经在考虑未来。原则上,这种材料产生电信号,具有自发性和选择性,这样,强化材料就可以在局部应力集中区域进行。损伤,比如形成裂缝的,就可以预防,甚至修复。这使科学家迈出了一大步,更接近他们目标中的“智能”高性能材料。

生物探索推荐英文原文

Material Turns Hard or Soft at the Touch of a Button

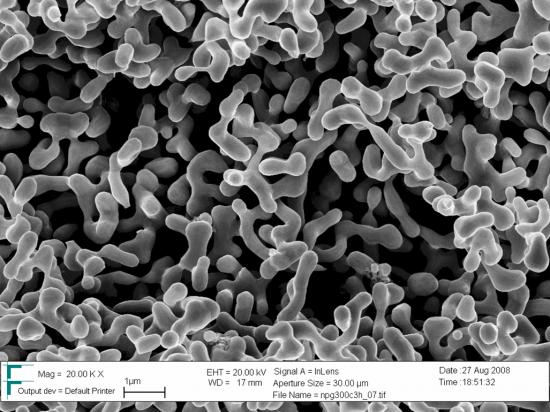

The nanomaterial under the scanning electron microscope.

A world premiere: a material which changes its strength, virtually at the touch of a button. This transformation can be achieved in a matter of seconds through changes in the electron structure of a material; thus hard and brittle matter, for example, can become soft and malleable. What makes this development revolutionary, is that the transformation can be controlled by electric signals.

This world-first has its origins in Hamburg. Jörg Weißmüller, a materials scientist at both the Technical University of Hamburg and the Helmholtz Center Geesthacht, has carried out research on this groundbreaking development, working in cooperation with colleagues from the Institute for Metal Research in Shenyang, China.

The 51-year-old researcher from the Saarland referred to his fundamental research, which opens the door to a multitude of diverse applications, as "a breakthrough in the material sciences." The new metallic high-performance material is described by Prof. Dr. Jörg Weißmüller and the Chinese research scientist Hai-Jun Jin in the latest issue of the scientific journal Science. Their research findings could, for example, make future intelligent materials with the ability of self healing, smoothing out flaws autonomously.

The firmness of a boiled egg can be adjusted at will through the cooking time. Some decisions are, however, irrevocable -- a hard-boiled egg can never be reconverted into a soft-boiled one. There would be less annoyance at the breakfast table if we could simply switch back and forth between the different degrees of firmness of the egg.

Similar issues arise in the making of structural materials such as metals and alloys. The materials properties are set once and for all during production. This forces engineers to make compromises in the selection of the mechanical properties of a material. Greater strength is inevitably accompanied by increased brittleness and a reduction of the damage tolerance.

Professor Weißmüller, head of the Institute of Materials Physics and Technology at the Technical University of Hamburg and also of the department for Hybrid Material Systems at the Helmholtz Center Geesthacht, stated: "This is a point where significant progress is being made. For the first time we have succeeded in producing a material which, while in service, can switch back and forth between a state of strong and brittle behavior and one of soft and malleable. We are still at the fundamental research stage but our discovery may bring significant progress in the development of so-called smart materials."

A Marriage of Metal and Water

In order to produce this innovative material, material scientists employ a comparatively simple process: corrosion. The metals, typically precious metals such as gold or platinum, are placed in an acidic solution. As a consequence of the onset of the corrosion process, minute ducts and holes are formed in the metal. The emerging nanostructured material is pervaded by a network of pore channels.

The pores are impregnated with a conductive liquid, for example a simple saline solution or a diluted acid, and a true hybrid material of metal and liquid is thus created. It is the unusual "marriage," as Weißmüller calls this union of metal and water which, when triggered by an electric signal, enables the properties of the material to change at the touch of a button.

As ions are dissolved in the liquid, the surfaces of the metal can be electrically charged. In other words, the mechanical properties of the metallic partner are changed by the application of an electric potential in the liquid partner. The effect can be traced back to a strengthening or weakening of the atomic bonding in the surface of the metal when extra electrons are added to or withdrawn from the surface atoms. The strength of the material can be as much as doubled when required. Alternatively, the material can be switched to a state which is weaker, but more damage tolerant, energy-absorbing and malleable.

Specific applications are still a matter for the future. However, researchers are already thinking ahead. In principle, the material can create electric signals spontaneously and selectively, so as to strengthen the matter in regions of local stress concentration. Damage, for instance in the form of cracks, could thereby be prevented or even healed. This has brought scientists a great step closer to their objective of 'intelligent' high performance materials.